06/11/2023 Elevating Bourbon Craftsmanship: Four Roses' AI Revolution in Spirits Production

Four Roses, a renowned American bourbon producer, has incorporated AI technology into its operations to enhance various aspects of their spirits production. Here's how Four Roses uses AI:

1. Quality Control:

AI systems are employed to monitor the production process in real time. They continuously analyze data from various stages of bourbon production, including mashing, fermentation, distillation, and aging. If any anomalies or deviations from the desired standards are detected, the AI can trigger immediate corrective actions, ensuring consistent product quality.

2. Predictive Maintenance:

Four Roses uses AI to predict when equipment, such as stills, tanks, and pumps, will require maintenance or replacement. By analyzing historical data and the performance of production machinery, AI algorithms can anticipate issues before they cause significant disruptions. This predictive maintenance approach minimizes downtime and ensures the distillery's equipment operates at peak efficiency.

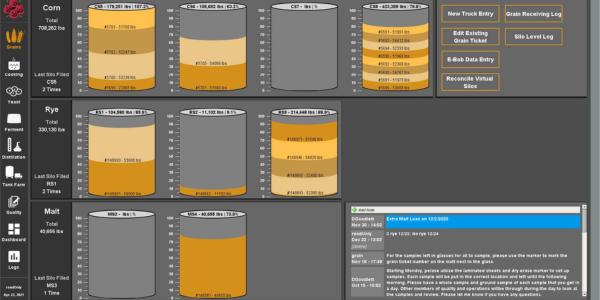

Image Source: Inductive Automation

The grains screen displays the grain silos at the distillery with the weight of the grain in pounds. In each silo graphic, the grain amounts are divided and color-coded by the corresponding truck ticket, so operators can easily see how much grain from each truckload is in a silo. The system records parameters like kernel damage, moisture level, foreign material, GMO, and other factors.

3. Process Optimization:

AI technology helps optimize the various stages of bourbon production. It can fine-tune factors such as temperature, humidity, and fermentation times to ensure that the bourbon reaches the desired flavor and aroma profiles consistently. This process optimization contributes to the creation of high-quality spirits.

4. Quality Assurance:

AI plays a crucial role in quality assurance by conducting rigorous analyses of the chemical composition and sensory characteristics of the bourbon throughout its maturation process. Any deviations from the desired attributes can be identified early, allowing for adjustments to be made to maintain product quality.

Image Source: Inductive Automation

Dashboard. The facility overview dashboard displays key highlights from the entire plant, allowing the user to see the most important information from each process stage in one convenient place.

5. Recipe Refinement:

Four Roses also leverages AI to refine its bourbon recipes. By analyzing consumer preferences, market trends, and historical sales data, AI algorithms can provide recommendations for recipe adjustments. This ensures that Four Roses' bourbon products align with evolving consumer tastes and preferences.

[[relatedPurchasesItems-31]]

6. Market Insights:

AI technology is used to gather and analyze vast amounts of market data, including consumer reviews, competitor performance, and emerging trends. This market insight helps Four Roses make informed decisions regarding product development, marketing strategies, and pricing.

Image: Four Roses Small Batch Select Bourbon, 93 Points, Gold Medal

By incorporating AI into their operations, Four Roses has been able to improve the consistency and quality of their bourbon production. AI's ability to provide real-time monitoring, predictive maintenance, and data-driven insights has not only optimized the distillery's processes but has also contributed to the overall efficiency and excellence of its spirits production.